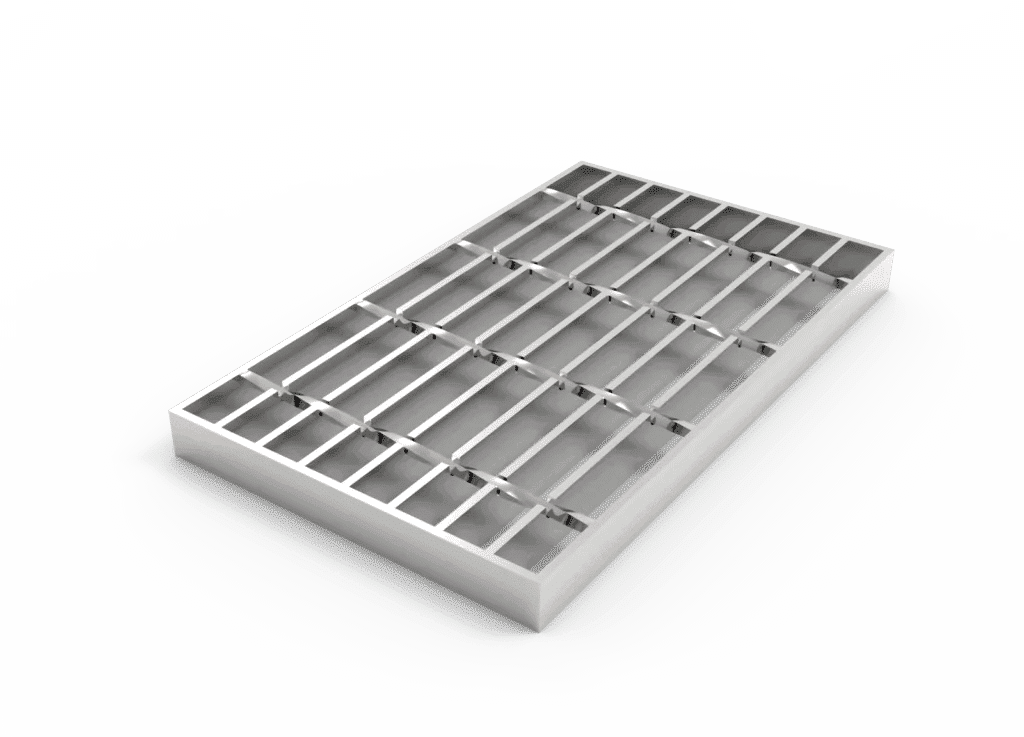

Galvanized steel grating is a popular choice in various industries for its durability, strength, and low maintenance needs. Galvanized steel grating is perfect for both indoor and outdoor use because it is made of premium steel and covered in a protective layer of zinc, which prevents corrosion and withstands harsh environments. In this article, we explore what galvanized steel grating is, its applications, benefits, types, and why it’s essential for industries seeking long-lasting solutions.

What is Galvanized Steel Grating?

Galvanized steel grating is a kind of metal grid used for ventilation grates, platforms, walkways, and flooring. To prevent rust and corrosion, the steel is galvanized, which involves applying a layer of zinc. Steel bars are usually welded or press-locked together to create the grating, which is an open grid with a stable, non-slip surface.

Key Benefits of Galvanized Steel Grating

- Corrosion Resistance: The zinc coating prevents rust, allowing it to endure extreme conditions and chemical exposure.

- Strength and Durability: Engineered for heavy loads, it supports high foot and vehicular traffic without deformation.

- Low Maintenance: Its durability reduces maintenance needs, making it a cost-effective choice over time.

- Slip Resistance: The grating’s textured surface minimizes slips, improving safety in industrial environments.

- Environmental Sustainability: Galvanized steel grating can be recycled, aligning with eco-friendly industrial practices.

Common Applications of Galvanized Steel Grating

Industrial Facilities: In industries like oil and gas, petrochemical, and mining, galvanized steel grating is widely used for catwalks, ramps, and maintenance platforms, offering safe, non-slip surfaces.

Commercial Buildings: Many modern structures incorporate galvanized steel grating in staircases, ventilation grates, and drainage covers, combining functionality with aesthetic appeal.

Public Infrastructure: From pedestrian walkways to drainage covers, galvanized steel grating is essential for infrastructure that requires durability and safety in public spaces.

Types of Galvanized Steel Grating

- Welded Steel Grating: Welded grating offers superior strength and is ideal for high-load areas. It is created by welding crossbars and bearing bars for stability.

- Press-Locked Steel Grating: The press-locked method combines bearing bars and crossbars under high pressure, offering precise openings and a smooth look.

- Swage-Locked Steel Grating: This type uses swaged crossbars inserted into pre-punched bearing bars, forming a durable and versatile structure suited for various load requirements.

Why Choose Galvanized Steel Grating?

Investing in galvanized steel grating ensures long-term performance, durability, and safety. Its ability to withstand extreme temperatures and environmental factors makes it a versatile choice for numerous industries. Since the zinc coating offers durable defense against corrosion and wear, the initial cost is offset by lower maintenance.

Choosing the Right Galvanized Steel Grating Supplier

When selecting a supplier, it’s essential to consider factors like quality standards, custom design options, and production capacity. A variety of options will be offered by trustworthy suppliers to meet the needs of your project, along with expert advice on selecting the best type and specifications.

Contact Us for High-Quality Galvanized Steel Grating

At China XB Wire Mesh, we are committed to delivering top-quality galvanized steel grating for industrial and commercial applications. With a focus on durability, safety, and exceptional service, we ensure you receive the best solution for your needs.

For inquiries, custom orders, and more information, contact us:

- Email: [email protected]

- Phone: +86 18732898388