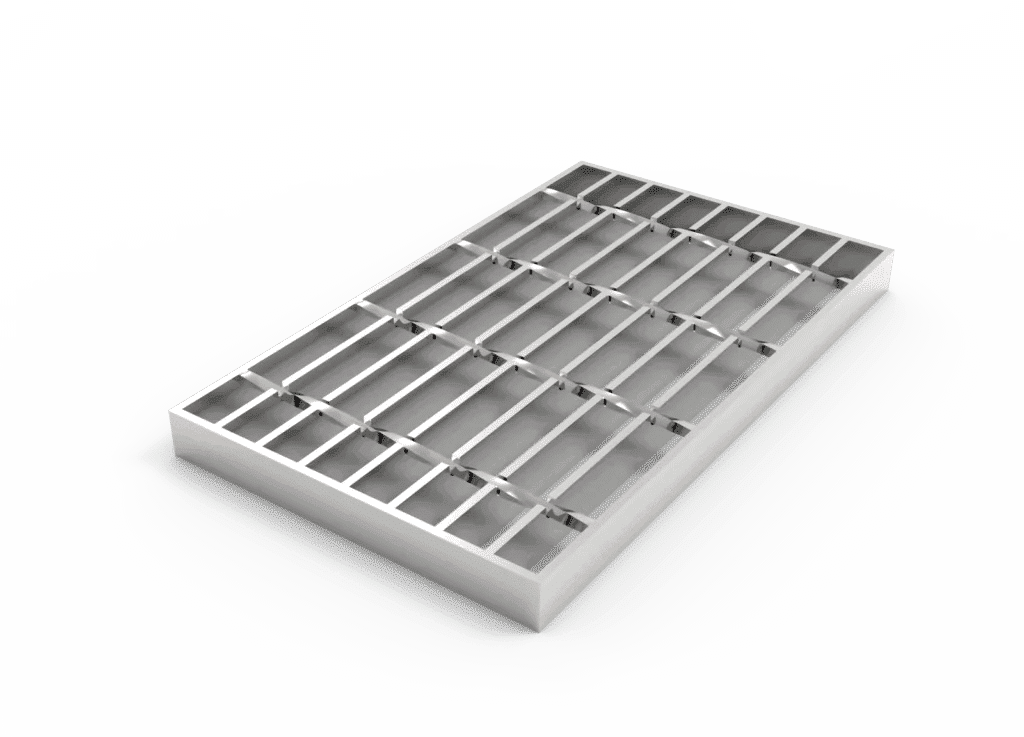

In architectural and industrial projects, steel bar grating is one of the most dependable and adaptable materials. This grating is made even more practical and aesthetically beautiful by adding a protective coat of paint, like the vivid red in the picture. Painted steel grating combines strength, safety, and corrosion resistance, making it a top choice for diverse applications.

What Is Painted Steel Bar Grating?

Painted steel bar grating is made from sturdy steel bars that are pressed or welded together for maximum stability and arranged in a grid pattern. Once the grating is formed, it undergoes a painting process, which:

- Improves corrosion resistance: The paint layer serves as a barrier, shielding the grating from moisture, chemicals, and other harmful substances.

- Enhances visibility: Vibrant colors, such as red, are frequently employed in safety applications to increase the visibility of walkways, platforms, and stair treads.

- Adds aesthetic appeal: Painted grating can complement the design elements of a building or structure.

Specifications of Painted Steel Bar Grating

Here’s a detailed table of typical specifications for painted steel grating:

| Specification | Details |

|---|---|

| Material | High-quality carbon steel or stainless steel |

| Surface Treatment | Painted (custom colors available; red shown in the image) |

| Load Bar Type | Serrated or plain (anti-slip options available) |

| Load Bar Size | Common sizes: 20×3 mm, 25×5 mm, 30×5 mm, or custom sizes |

| Cross Bar Spacing | Standard: 50 mm; Customizable per requirements |

| Load Bar Spacing | 30 mm, 40 mm, or as specified |

| Coating Thickness | Typically 30–50 microns (varies with paint type) |

| Corrosion Resistance | High; suitable for harsh and outdoor environments |

| Weight Capacity | Varies based on size; supports heavy loads |

| Applications | Industrial flooring, platforms, walkways, stair treads |

Common Applications

Painted steel bar grating finds applications across numerous industries, including:

- Industrial Facilities: Used on platforms, catwalks, and floors where safety and durability are critical.

- Oil and Gas: Provides secure walkways in offshore platforms and refineries.

- Architecture: Adds a modern touch to facades, sunshades, or fences while maintaining strength.

- Public Spaces: Used in stair treads, drainage covers, or pedestrian pathways for its load-bearing capacity and slip resistance.

- Marine Environments: The painted coating helps resist corrosion from saltwater exposure.

Why Choose Painted Steel Grating?

- Enhanced Safety: The bold paint improves visibility, making it a safer option for hazardous areas.

- Low Maintenance: Painted grating requires minimal upkeep, as the coating protects it from environmental damage.

- Cost-Effectiveness: Its longevity and resilience make it a cost-effective solution in the long term.

Caring for Painted Steel Bar Grating

To maximize the lifespan of painted steel grating:

- Perform regular inspections to check for chips or scratches in the paint.

- Reapply paint as needed to maintain its protective qualities.

- Clean the grating periodically to remove debris, dirt, or corrosive agents.

Conclusion

Painted steel bar grating is a versatile option for projects requiring durability, safety, and style. Its painted surface protects the underlying steel while also improving its usefulness and look. Whether for architectural or industrial applications, painted steel grating is a dependable option that fulfills the highest performance and aesthetic criteria.

If you’re looking for high-quality painted steel grating tailored to your needs, feel free to contact us at [email protected] or call us at +86 18732898388.