- Global delivery straight from the manufacturer to your doorstep.

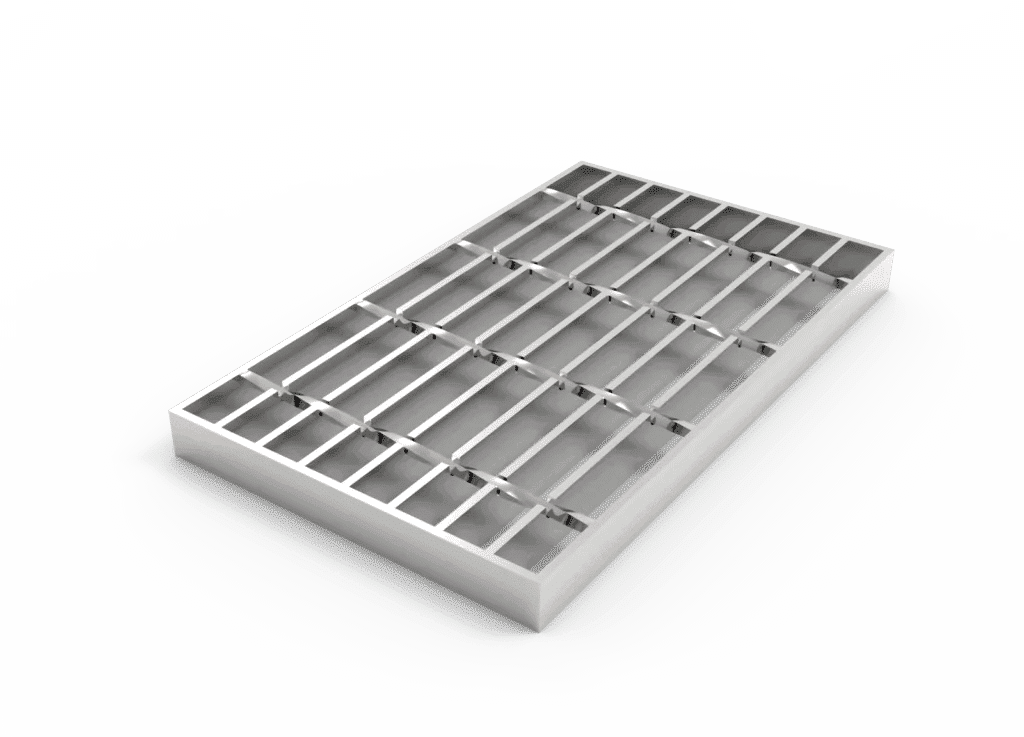

Galvanized Steel Grating

Galvanized Steel Grating

Durable. Reliable. Precision-Engineered Galvanized Steel Grating

What is

Galvanized Steel Grating?

Galvanized steel grating finds a wide range of applications, from industry to commerce. It is manufactured with superior quality carbon steel by coating it with zinc, which makes it resistant to corrosion even in the most extreme conditions. This robust construction ensures long-term performance, making it a reliable choice for demanding environments such as manufacturing plants, warehouses, and outdoor facilities. Its anti-slip properties and high load-bearing capacity further enhance its practicality in various settings.

Features That Set Us Apart

Corrosion Resistance

Corrosion Resistance: Coated with a zinc layer, our grating offers excellent corrosion resistance, ensuring long-term durability even in harsh environments.

High Load-Bearing Strength

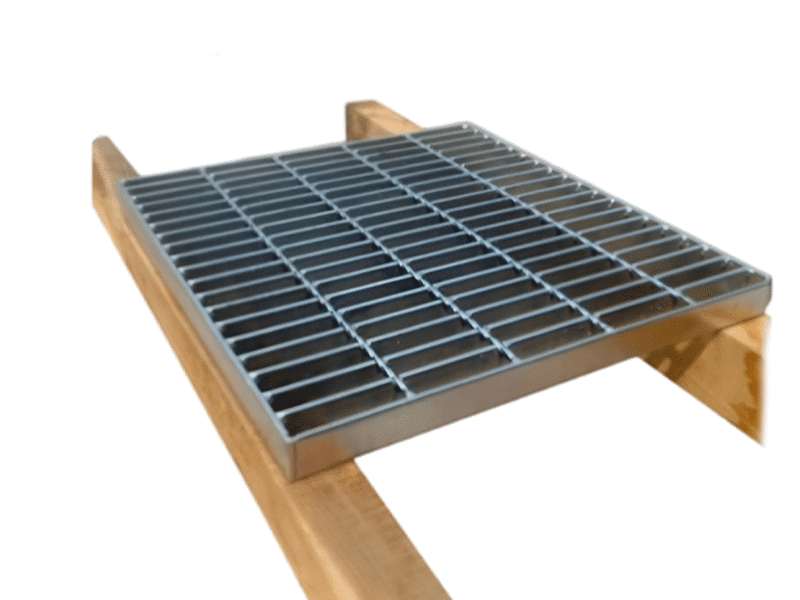

Designed for durability, our grating provides exceptional load-bearing capacity, making it ideal for heavy-duty applications like walkways and industrial platforms.

Customizable Sizes

Choose from a range of standard sizes or request custom configurations to perfectly suit your project’s needs, ensuring a seamless and efficient installation.

Why Choose

Galvanized Steel Grating

Galvanized Steel Grating, designed to handle heavy loads effortlessly. Its zinc coating ensures exceptional resistance to rust, making it a low-maintenance solution for long-term use. Prioritizing safety, the anti-slip surface provides reliable traction even in wet conditions. Plus, our grating is fully customizable, tailored to meet the specific needs of your project, ensuring a perfect fit every time.

CONTACT ME LEARN MORE

Features & Characteristics

Galvanized steel grating is the ideal choice for heavy-duty infrastructure projects, offering a blend of performance, durability, and aesthetic value. Whether for industrial, commercial, or public applications, it delivers reliability and long-term satisfaction. Galvanized steel grating offers a superior solution for demanding applications, combining durability, functionality, and cost-effectiveness. Its standout features and characteristics include:

1. High Strength and Toughness

Engineered for exceptional load-bearing capacity, galvanized steel grating is significantly stronger and tougher than traditional cast iron alternatives. This makes it suitable for large-span and heavy loading conditions, such as those encountered in terminals, airports, and other high-traffic areas.

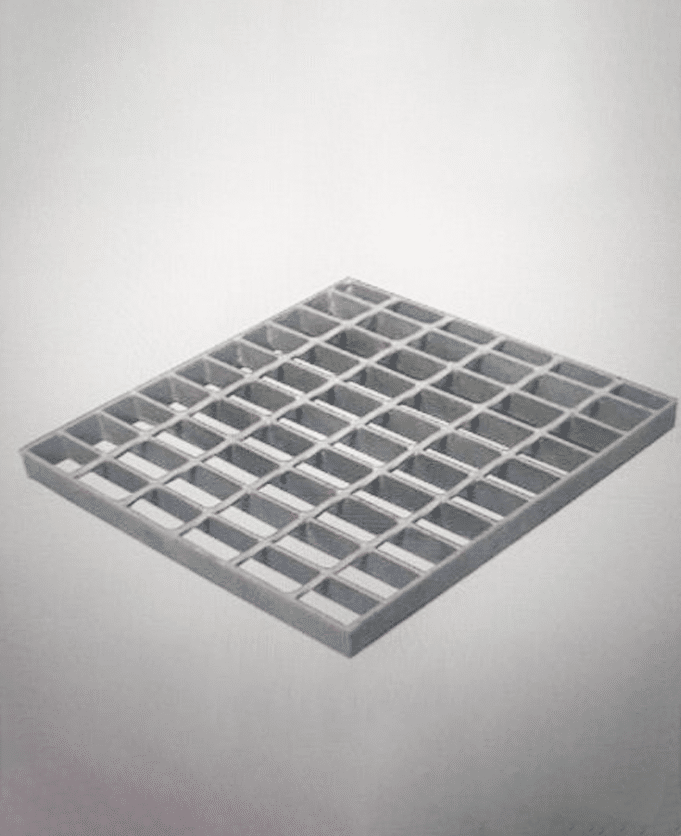

2. Hot-Dip Galvanized Treatment

To enhance longevity and resilience, the grating undergoes a hot-dip galvanization process. This provides outstanding rust-proof and corrosion-resistant properties, ensuring a maintenance-free, long-lasting solution that stands up to varying weather conditions.

3. Anti-Theft Design

Security and safety are prioritized with a smart anti-theft design. The cover and frame are integrated with a hinge, offering enhanced protection, reducing the risk of theft, and allowing for easy and convenient access when needed.

4. Cost-Effectiveness

Galvanized steel grating outperforms cast iron in terms of cost-efficiency. Its high strength minimizes the risks of damage under heavy loads, and the integrated anti-theft design eliminates the financial loss associated with stolen or broken components. This translates into substantial savings on repairs, replacements, and investment in higher-quality materials.

5. Aesthetic Appeal

With sleek, simple lines and a modern silver finish, galvanized steel grating complements contemporary architectural trends. Its clean, professional appearance ensures it blends seamlessly into any design while providing functional excellence.

6. Superior Drainage Performance

The advanced design includes a leakage area of 83.3 percent—more than double that of traditional cast iron solutions. This efficient drainage capacity ensures rapid water removal, reducing the risk of pooling and flooding in areas requiring optimal water management.

Applications of Galvanized Steel Grating

Given its strength and versatility, galvanized steel grating is an ideal choice for a wide variety of applications, including: